Robots have always fascinated us, from the earliest tales of mechanical beings to the cutting-edge technology we see today. But within the realm of robotics, there’s a new kid on the block that’s been making waves – the cobot. In this showdown, we’re going to dive deep into the world of cobots and traditional robots, exploring their differences, similarities, and what sets them apart in various industries.

What’s the Difference?

Okay, before we jump into the ring and watch cobots and robots duke it out, let’s clarify what these two contenders really are.

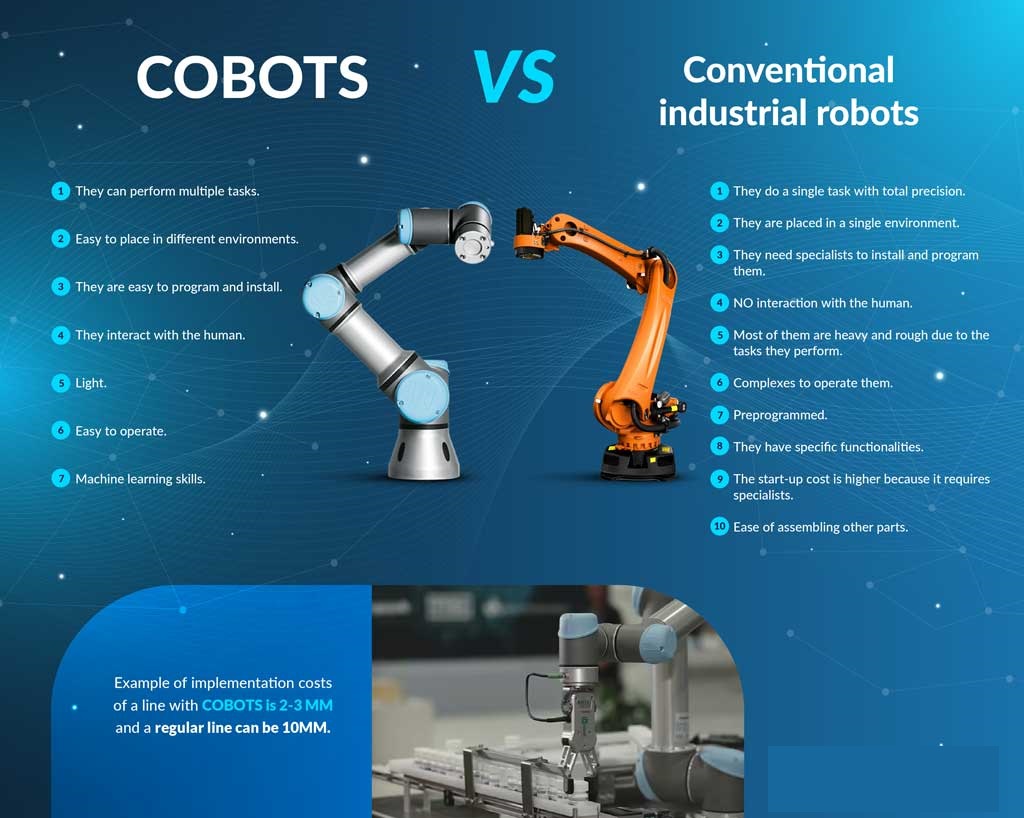

Robots: Think of robots as the heavyweight champions of automation. They are typically standalone machines designed to perform a specific task, often in isolation from humans. Traditional robots are like the solo artists of the automation world – they do their thing without needing much interaction or collaboration.

Cobots: Cobots, on the other hand, are the social butterflies of automation. Short for “collaborative robots,” cobots are designed to work alongside humans, sharing the same workspace. They’re more like the members of a band, harmoniously playing their roles to create a beautiful symphony of productivity.

Now that we know the basics, let’s explore how these two contenders measure up in various categories.

Round 1: Safety First

Cobots: When it comes to safety, cobots have a distinct advantage. They are built with sensors and software that allow them to detect and react to human presence. If a cobot senses that it’s getting too close to a human co-worker, it can slow down or stop entirely, preventing any potential accidents. This makes them a great choice for industries where human-robot collaboration is essential, like manufacturing and healthcare.

Robots: Traditional robots, while powerful and precise, often lack the safety features of cobots. They typically operate in fenced-off areas or behind safety barriers to prevent any accidental human interaction. This limits their use in environments where close collaboration with humans is necessary.

Verdict: Cobots take the first round for their human-friendly approach.

Round 2: Flexibility and Adaptability

Cobots: Cobots are known for their flexibility. They can be easily reprogrammed to perform a new task, making them ideal for businesses that require quick changes in production. This adaptability means that cobots can move from one task to another, making them a versatile addition to any workforce.

Robots: Traditional robots are specialized machines. They are designed to excel at a specific task, but reprogramming them for a new job can be a complex and time-consuming process. This lack of flexibility can be a drawback in industries where production lines need to pivot rapidly.

Verdict: Cobots win this round for their chameleon-like ability to adapt to new tasks.

Round 3: Cost and Return on Investment

Cobots: The initial cost of cobots can be lower than that of traditional robots, making them an attractive option for small to medium-sized businesses. Additionally, cobots are often seen as an investment in productivity and safety, with the potential for a quick return on investment (ROI) due to increased efficiency and reduced workplace accidents.

Robots: Traditional robots can be expensive to purchase, install, and maintain. However, for large-scale manufacturing operations with high production volumes, the ROI over time can justify the initial cost.

Verdict: Cobots win this round for their affordability and potential for quick ROI.

Round 4: Speed and Precision

Cobots: Cobots are designed to work at human-friendly speeds, which means they may not be as fast as traditional robots in certain applications. However, their precision and accuracy make them well-suited for tasks that require delicate handling, like assembling small electronic components.

Robots: Traditional robots excel in speed and precision. They can perform repetitive tasks at high speeds with incredible accuracy, making them indispensable in industries where efficiency and precision are paramount.

Verdict: Robots take this round for their blazing speed and pinpoint accuracy.

Round 5: Programming and Ease of Use

Cobots: Cobots are designed to be user-friendly. They often come with intuitive programming interfaces that allow non-experts to set up and operate them with minimal training. This accessibility makes cobots an attractive option for businesses with limited technical expertise.

Robots: Traditional robots typically require specialized programming skills, and their interfaces can be complex. This means that businesses may need to invest in training or hire skilled technicians to operate and maintain them.

Verdict: Cobots win this round for their user-friendly design.

Round 6: Application Variety

Cobots: Cobots are highly adaptable and can be found in various industries, from manufacturing and healthcare to agriculture and logistics. They thrive in situations where human-robot collaboration is essential.

Robots: Traditional robots are prevalent in industries like automotive manufacturing, where they excel in repetitive, high-speed tasks. They are less common in industries that require close interaction with humans.

Verdict: Cobots take the lead in application variety.

Round 7: Job Impact

Cobots: Cobots are often seen as partners to human workers rather than replacements. They can take on the monotonous and physically demanding tasks, freeing up humans to focus on more creative and complex aspects of their jobs. This collaboration can enhance job satisfaction and retention.

Robots: Traditional robots can lead to concerns about job displacement, especially in industries where automation is heavily adopted. While they create new job opportunities in areas like robot maintenance and programming, they can also lead to the displacement of certain manual labor positions.

Verdict: Cobots win the round for their potential to enhance human work rather than replace it.

Round 8: Size and Space

Cobots: Cobots are often compact and designed to fit into existing workspaces without major modifications. This makes them a good choice for businesses with limited floor space.

Robots: Traditional robots can vary in size, but some industrial robots can be quite large and require significant floor space and safety measures.

Verdict: Cobots win this round for their space-saving design.

Round 9: Maintenance

Cobots: Cobots are designed with ease of maintenance in mind. Their user-friendly interfaces often come with diagnostic tools to identify issues quickly. Some cobots can even perform self-maintenance to a certain extent.

Robots: Traditional robots may require more extensive maintenance, and downtime for repairs can impact production schedules. Skilled technicians are often needed for robot maintenance.

Verdict: Cobots win this round for their maintenance simplicity.

Round 10: The Human Touch

Cobots: Cobots are all about collaboration. They’re designed to work with humans and can assist with tasks that require a human touch, such as delicate assembly or patient care in healthcare settings.

Robots: Traditional robots, with their speed and precision, are better suited for tasks that require repetitive actions and high levels of precision but may lack the human touch in more delicate operations.

Verdict: Cobots win this round for their ability to add the human touch to automation.

The Final Bell: Who’s the Winner?

After ten rounds of intense competition, it’s clear that cobots and traditional robots each have their strengths and weaknesses. The winner depends on the specific needs of the industry and the tasks at hand.

- Cobots are the champions of collaboration, safety, flexibility, and ease of use. They’re the perfect partners for industries that require human-robot teamwork, adaptability, and a friendly user interface.

- Robots, on the other hand, dominate in terms of speed, precision, and raw power. They shine in industries where high-speed, high-precision automation is crucial and where human interaction can be minimized.

So, it’s not a knockout victory for either side. Instead, it’s more like a tag-team match where cobots and traditional robots can complement each other in different industries and applications.

FAQs

Q1: Can cobots completely replace traditional robots in manufacturing?

A1: While cobots offer advantages in safety and collaboration, traditional robots still excel in high-speed, precision manufacturing tasks. The choice between cobots and traditional robots depends on the specific needs of the manufacturing process.

Q2: Are cobots more cost-effective in the long run?

A2: Cobots can be more cost-effective for small to medium-sized businesses due to their lower initial cost and potential for quick ROI. However, for large-scale manufacturing, traditional robots may provide a higher long-term return on investment.

Q3: Can cobots be used in healthcare settings?

A3: Yes, cobots are increasingly being used in healthcare for tasks like patient care, medication delivery, and disinfection. Their ability to work safely alongside humans makes them valuable in healthcare environments.

Q4: Do cobots require specialized training to operate?

A4: Cobots are designed to be user-friendly, and many come with intuitive programming interfaces. While some training may be necessary, it is typically less extensive than what is required for traditional robots.

Q5: Are traditional robots becoming obsolete?

A5: Traditional robots are not becoming obsolete; they still have a crucial role in industries that require high-speed, high-precision automation. However, cobots are expanding automation possibilities in industries that require collaboration with humans.